Unearthing The Stone Cutter's Secret: Crafting With Precision

In a world increasingly dominated by synthetic materials and rapid production, there remains an enduring fascination with the raw, elemental beauty of stone. The phrase "stone cutter recipe" might immediately bring to mind virtual crafting tables in popular video games, but the true essence of this concept delves much deeper, touching upon millennia of human ingenuity, skill, and an intimate understanding of one of Earth's most fundamental resources. It's not merely about combining ingredients; it's about mastering a timeless craft that has shaped civilizations, built monuments, and continues to define our physical spaces.

From the colossal structures of ancient empires to the intricate details of modern architecture, the ability to transform raw stone into functional and beautiful forms has been a cornerstone of human development. This article will explore the multifaceted "stone cutter recipe," not as a simple list of items, but as a comprehensive guide to the knowledge, techniques, and artistry involved in working with stone. We'll uncover the historical significance, modern advancements, and the inherent properties of stone that make this craft both challenging and incredibly rewarding, providing insights that go far beyond any virtual blueprint.

Table of Contents

- The Enduring Legacy of Stone: More Than Just a Rock

- Decoding the "Stone Cutter Recipe": A Craft of Precision

- Ancient Foundations: Stone Cutting Through the Ages

- The Modern Stone Cutter's Arsenal: Tools and Techniques

- Applications of the Stone Cutter's Craft: Beyond Basic Building

- The "Recipe" for Success: Skills and Knowledge for the Stone Cutter

- The Economic and Aesthetic Value of Stone Craftsmanship

- Embracing the Future: Innovation in Stone Cutting

The Enduring Legacy of Stone: More Than Just a Rock

To truly understand the "stone cutter recipe," one must first appreciate the material itself. Stone, in its essence, is a concretion of earthy or mineral matter, a hard substance that comes from the ground. It is formed of rocks that comprise the crust of the earth, and therefore, it has no regular shape in its natural state. This inherent variability is part of its charm and challenge. Historically, stones were some of the essential construction materials in civil engineering, laying the very foundations of human civilization.

The term "stone" also carries diverse meanings. While our focus is on its physical properties as a building material, it's worth noting its historical use as a unit of mass, particularly in English and British imperial systems, where a stone (St.) equals 14 avoirdupois pounds (6.35 kg). This historical weight unit underscores stone's long-standing significance in trade and measurement. However, for the stone cutter, it's the material's durability, aesthetic appeal, and structural integrity that truly matter. A small piece of rock, or a larger detached piece that has been broken off or shaped, typically by natural processes or human activity, is what a stone cutter works with. Another name for a stone, or hard mineral lump, is a rock, emphasizing its fundamental nature.

Decoding the "Stone Cutter Recipe": A Craft of Precision

When we talk about a "stone cutter recipe," we're not referring to a list of ingredients in a cookbook. Instead, it embodies the accumulated knowledge, specialized tools, precise techniques, and artistic vision required to transform raw stone into a finished product. It's a craft that demands patience, an understanding of geology, and an eye for detail. The "recipe" for a stone cutter is an intricate blend of traditional wisdom passed down through generations and modern technological advancements.

At its core, the stone cutter's recipe involves a series of deliberate steps: selecting the right stone, understanding its inherent characteristics (such as its grain, hardness, and potential for cleavage), and then employing the correct methods to cut, shape, and finish it. This process varies dramatically depending on the type of stone, its intended use, and the desired aesthetic. Whether it's creating a sturdy foundation, an ornate sculpture, or a sleek countertop, the underlying "recipe" is one of precision, respect for the material, and unwavering dedication to quality.

Ancient Foundations: Stone Cutting Through the Ages

The history of the "stone cutter recipe" is as old as civilization itself. Early humans quickly recognized the utility of stone, using it for tools, weapons, and eventually, shelter. The earliest methods of stone cutting were rudimentary, relying on the principle of percussion. Larger stones were broken down using smaller, harder stones as hammers, or by exploiting natural fissures. As societies evolved, so did the tools and techniques.

The ancient Egyptians, Greeks, and Romans were master stone cutters, achieving feats of engineering and artistry that still astound us today. They developed sophisticated methods for quarrying massive blocks, transporting them, and then precisely shaping them using copper, bronze, and later, iron tools. Simple wedges, chisels, and mallets were the primary instruments in their "stone cutter recipe." The precision with which they cut and fitted massive blocks for pyramids, temples, and aqueducts demonstrates an extraordinary level of expertise and a deep understanding of the material, long before the advent of power tools.

The Art of Quarrying: Extracting the Raw Material

Before any shaping can begin, the stone must be extracted from the earth. Quarrying is the initial, fundamental step in the stone cutter's recipe. Historically, this involved identifying suitable rock formations, then using methods like fire-setting (heating the rock and then rapidly cooling it to induce cracks) or driving wedges into natural fissures. With the advent of gunpowder, blasting became a more efficient, albeit less precise, method of extraction.

Modern quarrying employs highly specialized machinery, including diamond-wire saws that can cut through vast sections of rock with incredible precision, minimizing waste and damage to the extracted blocks. Once quarried, these large blocks are often rough-cut into more manageable sizes at the quarry site before being transported to workshops for further processing. This initial shaping is crucial, as it sets the stage for the subsequent, more refined stages of the stone cutter's craft.

The Modern Stone Cutter's Arsenal: Tools and Techniques

The "stone cutter recipe" has been revolutionized by technological advancements, transforming a laborious manual craft into a high-precision industry. While traditional hand tools like chisels, hammers, and mallets still have their place, especially in restoration work or intricate carving, modern stone cutters rely heavily on power tools and automated machinery.

Diamond-bladed saws, ranging from handheld circular saws to massive bridge saws, are indispensable for cutting large slabs and precise dimensions. Grinders and polishers, equipped with abrasive pads, are used to achieve various finishes, from rough textures to mirror-like gleam. Waterjet cutters, which use high-pressure streams of water mixed with abrasive particles, can cut intricate shapes and patterns with unparalleled accuracy, even through the hardest stones. Computer Numerical Control (CNC) machines have further automated the stone cutter recipe, allowing for complex designs to be programmed and executed with minimal human intervention, ensuring consistency and efficiency.

From Rough Block to Refined Form: The Shaping Process

Once the raw stone block arrives at the workshop, the true artistry of the "stone cutter recipe" begins. The shaping process involves several stages, each requiring specific tools and skills:

- Sizing and Squaring: Large blocks are cut into precise dimensions using bridge saws or gang saws to create slabs or smaller blocks suitable for the final product.

- Cutting to Pattern: For countertops, tiles, or architectural elements, templates or digital designs guide the cutting of specific shapes using circular saws, waterjets, or CNC machines.

- Edge Profiling: The edges of the stone are shaped and smoothed using routers, grinders, or specialized edge-profiling machines. Common profiles include bullnose, ogee, bevel, and straight edges.

- Finishing: This is where the aesthetic appeal of the stone is brought out. Finishes can range from a rough, natural split face to a highly polished, reflective surface. Other common finishes include honed (matte), flamed (textured), sandblasted, or brushed, each altering the appearance and feel of the stone.

- Carving and Detailing: For sculptural work or intricate architectural elements, skilled artisans use a combination of hand tools and specialized power tools to carve details, relief work, and decorative elements.

This multi-stage process highlights that the "stone cutter recipe" is not a single action but a series of carefully executed steps, each building upon the last to achieve the desired outcome.

Applications of the Stone Cutter's Craft: Beyond Basic Building

The versatility of stone, combined with the precision of the stone cutter's craft, means its applications are incredibly diverse. As mentioned, stones were some of the essential construction materials in civil engineering, forming the backbone of infrastructure. But the reach of the "stone cutter recipe" extends far beyond:

- Architecture: Stone is widely used for building facades, interior flooring, wall cladding, staircases, and intricate architectural details. Its durability and timeless aesthetic make it a preferred choice for both residential and commercial projects.

- Kitchens and Bathrooms: Granite, marble, and quartz countertops are highly sought after for their beauty, durability, and resistance to heat and scratches. Stone sinks and shower surrounds also add a touch of luxury.

- Sculpture and Art: From classical statues to modern abstract forms, stone has been a favored medium for artists throughout history. The stone cutter's skill is paramount in translating artistic vision into tangible form.

- Landscaping: Stone is integral to outdoor design, used for pavers, retaining walls, garden benches, fountains, and decorative elements.

- Monuments and Memorials: The enduring nature of stone makes it ideal for commemorating events and individuals, ensuring their memory lasts for generations.

- Infrastructure: Bridges, dams, and certain road elements still utilize cut stone for its strength and longevity.

Whatever color or style you need for your design, the ability to manipulate stone allows for everything from inspiration to installation of your manufactured and natural stone veneer, offering unparalleled design flexibility.

Natural vs. Manufactured Stone: Understanding Your Materials

The "stone cutter recipe" also adapts to the type of material being worked with. While natural stone (such as granite, marble, limestone, and slate) is quarried directly from the earth, manufactured stone, or engineered stone, is a composite material made from crushed stone (often quartz) mixed with resins and pigments. Additionally, stone veneer, whether natural or manufactured, provides the aesthetic of solid stone with lighter weight and easier installation.

- Natural Stone: Each piece is unique, with variations in color, pattern, and veining. It requires specific cutting techniques due to its natural grain and potential for inclusions. Understanding the specific properties of each natural stone type is a crucial part of the stone cutter's recipe.

- Manufactured Stone: Offers consistent color and pattern, and is often less porous than natural stone. It can be easier to cut and work with due to its uniform composition, though specific tools are still required to avoid chipping or cracking the resin binder.

- Stone Veneer: These are thin slices of natural stone or manufactured panels designed to mimic the look of full-sized stone blocks. The "recipe" for working with veneer focuses more on precise cutting for fit and adhesion techniques, rather than deep shaping.

A skilled stone cutter understands the nuances of each material, adapting their "recipe" of tools and techniques to achieve the best results.

The "Recipe" for Success: Skills and Knowledge for the Stone Cutter

Beyond the tools and the material, the true "stone cutter recipe" lies within the individual's expertise. It's a combination of practical skills, theoretical knowledge, and an artistic sensibility. A successful stone cutter possesses:

- Material Knowledge: A deep understanding of different stone types, their geological properties, hardness, porosity, and how they react to various cutting and finishing processes.

- Precision and Accuracy: The ability to measure, mark, and cut with extreme precision, often to within fractions of a millimeter, is paramount for a seamless fit and finish.

- Tool Proficiency: Mastery of both traditional hand tools and modern power equipment, knowing which tool to use for each specific task and how to maintain them.

- Problem-Solving Skills: The ability to anticipate challenges, troubleshoot issues that arise during cutting, and adapt techniques to unexpected variations in the stone.

- Safety Awareness: Working with heavy machinery and abrasive materials demands strict adherence to safety protocols to prevent injury.

- Artistic Vision (for carvers): For those involved in sculptural or decorative work, an understanding of form, proportion, and aesthetics is crucial.

The meaning of stone to a craftsman is not just a hard substance, but a canvas waiting to be transformed, requiring both technical prowess and creative insight.

Preserving the Craft: Education and Apprenticeship

The "stone cutter recipe" is a body of knowledge that has been refined over millennia, and its preservation is vital. Many modern stone cutters learn their trade through apprenticeships, working alongside experienced masters who pass down practical skills and nuanced understanding. Formal education programs in masonry, stone carving, and architectural restoration also play a crucial role in teaching the principles of the stone cutter's craft, blending historical techniques with modern technology.

These programs ensure that the intricate "recipe" for working with stone continues to evolve and thrive, attracting new generations to a profession that combines physical labor with artistic expression and intellectual challenge. By documenting techniques, sharing knowledge, and fostering a passion for the material, the legacy of the stone cutter endures.

The Economic and Aesthetic Value of Stone Craftsmanship

The investment in a skilled stone cutter and quality stone materials yields significant returns, both economically and aesthetically. Stone is renowned for its exceptional durability and longevity. Structures and features made of stone can last for centuries, often outliving other building materials. This makes it a sustainable choice, reducing the need for frequent replacements and minimizing waste.

Aesthetically, stone offers a timeless appeal that transcends fleeting trends. Its natural beauty, with unique patterns, colors, and textures, adds a sense of luxury, permanence, and connection to nature. Whether it's the grandeur of a granite facade, the warmth of a limestone floor, or the intricate details of a marble sculpture, stone craftsmanship elevates spaces and enhances property value. The "stone cutter recipe" contributes to creating environments that are not only functional but also deeply inspiring and visually captivating.

Embracing the Future: Innovation in Stone Cutting

While rooted in ancient traditions, the "stone cutter recipe" continues to evolve. Innovations in machinery, software, and material science are constantly pushing the boundaries of what's possible. Robotics, advanced CNC systems, and 3D scanning technologies are allowing for even greater precision, efficiency, and the creation of increasingly complex forms. New composite materials and bonding agents are also expanding the possibilities for stone applications.

Despite these technological advancements, the fundamental principles of understanding the material, mastering the tools, and possessing an eye for detail remain at the heart of the stone cutter's craft. The human element—the expertise, the judgment, and the artistic touch—will always be an indispensable ingredient in the "stone cutter recipe." The future of stone cutting is a harmonious blend of ancient wisdom and cutting-edge innovation, ensuring that this noble material continues to shape our world for generations to come.

Conclusion

The "stone cutter recipe" is far more than a simple set of instructions; it is a profound testament to human ingenuity, patience, and the enduring relationship between humanity and the natural world. From the earliest rudimentary tools used to shape a small piece of rock to the sophisticated CNC machines of today, the journey of transforming raw stone into magnificent structures and works of art is a continuous narrative of skill and dedication. It's about understanding that hard substance that comes from the ground, recognizing its potential, and applying a precise blend of knowledge and technique to bring that potential to life.

Whether you're an aspiring craftsman, an architect, or simply someone who appreciates the beauty of stone, delving into the intricacies of this craft reveals a rich tapestry of history, technology, and artistry. We hope this exploration has deepened your appreciation for the meticulous work involved in stone cutting. What aspects of the stone cutter's craft do you find most fascinating? Share your thoughts in the comments below, or explore more articles on our site about the timeless materials that build our world!

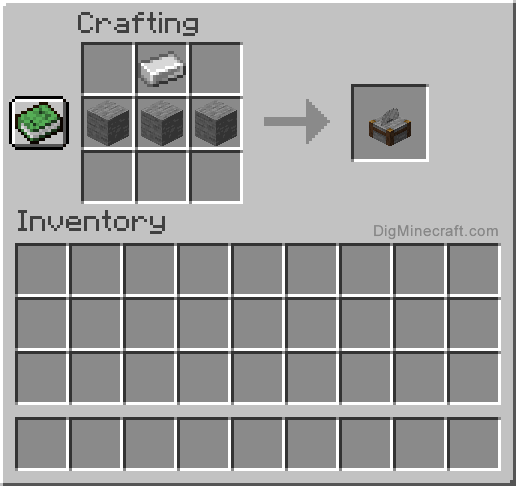

How to Make a Stonecutter in Minecraft: 7 Easy Steps

How to Make a Stonecutter in Minecraft | DiamondLobby

How to make a Stonecutter in Minecraft